-

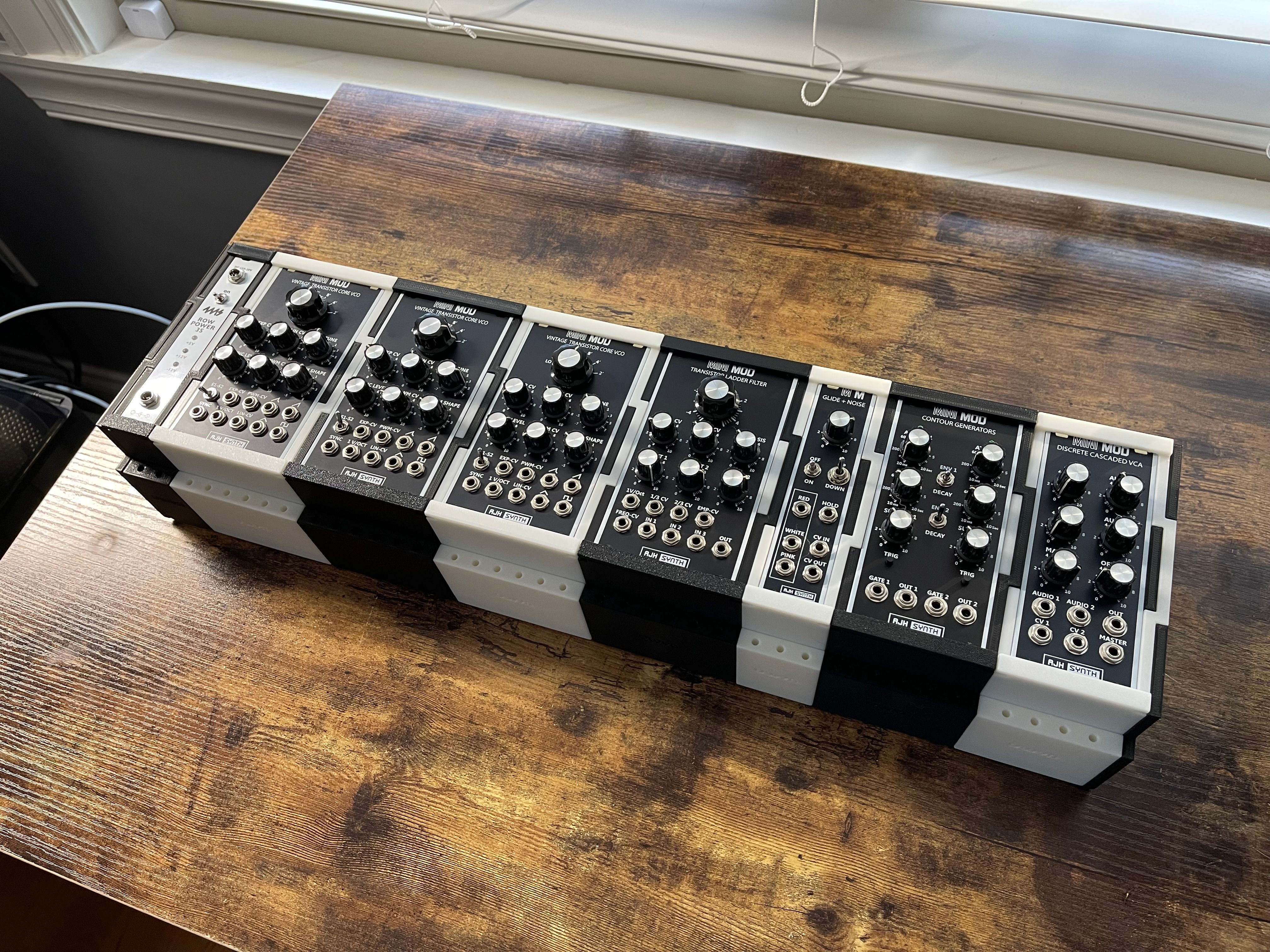

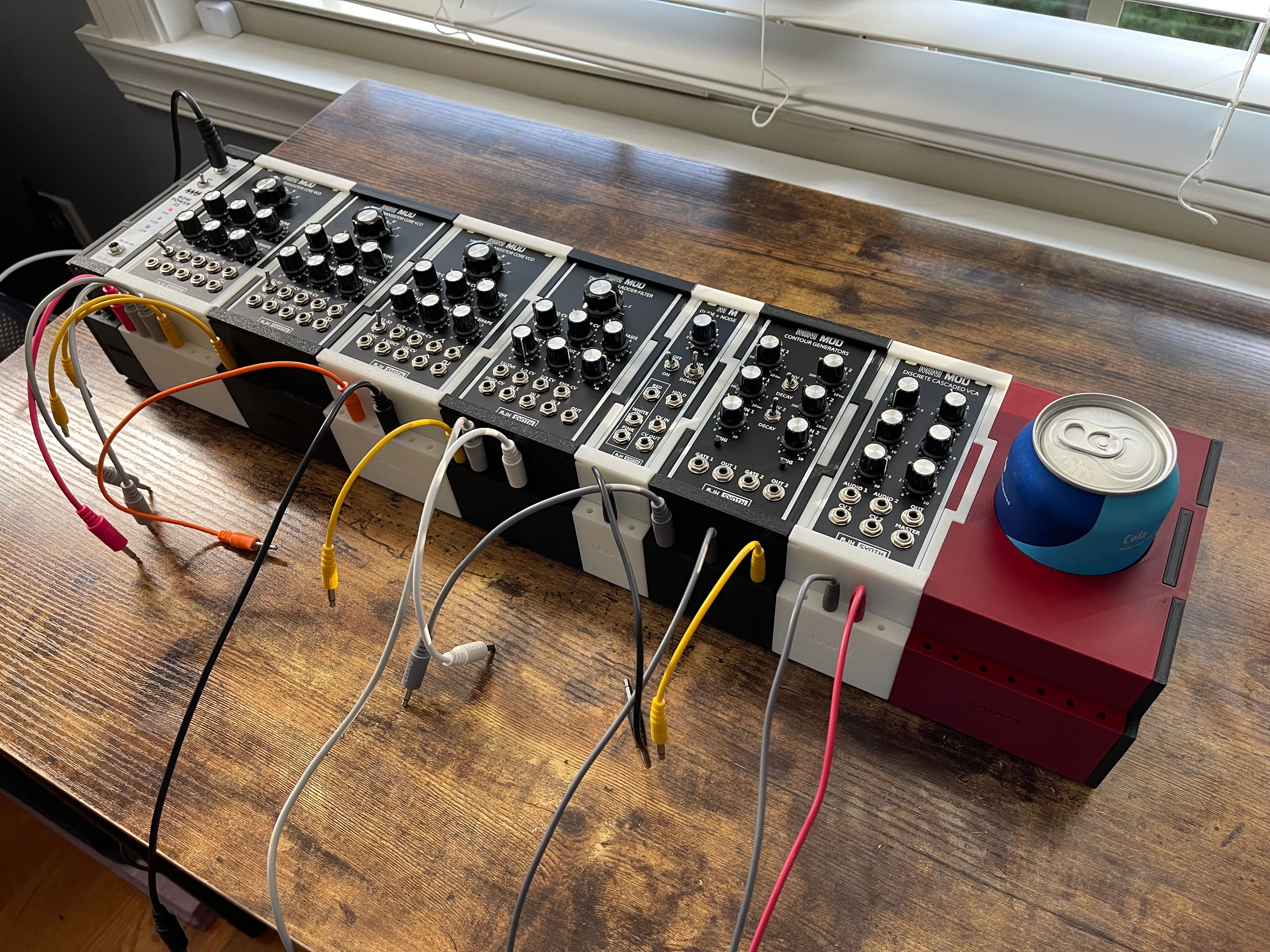

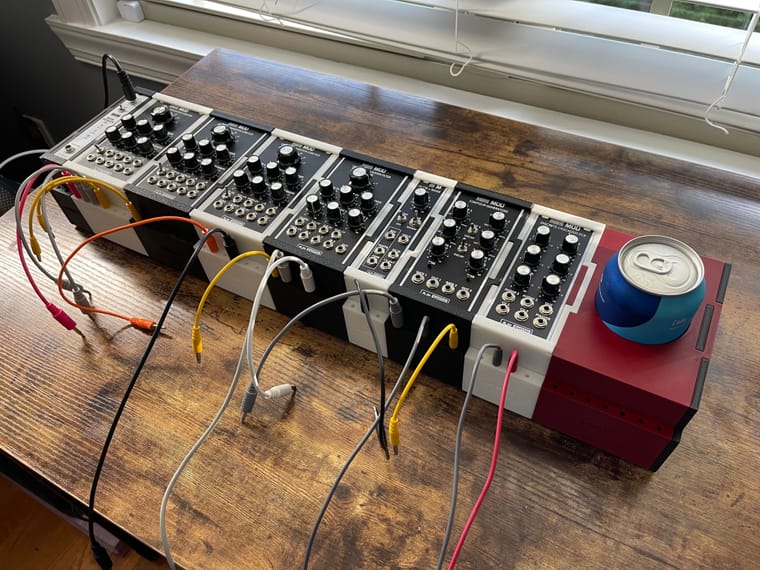

I've been experimenting with a freely reararrangeable 3D printed Eurorack case solution and I'm far enough along that I decided to build a complete case for my AJH MiniMod system.

I've received a lot of questions for the last week, so here are a few photos that show some of the assemble and features.

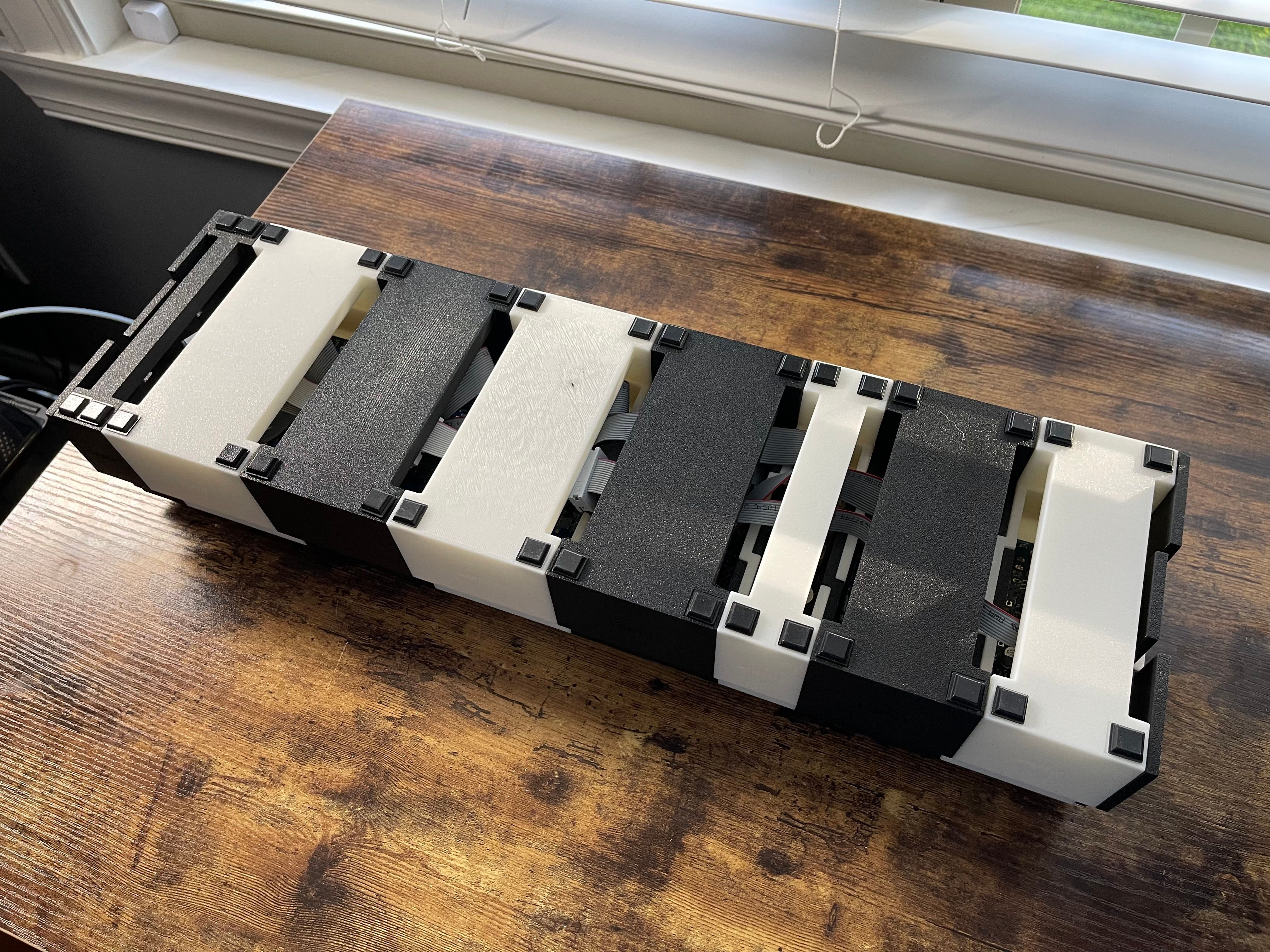

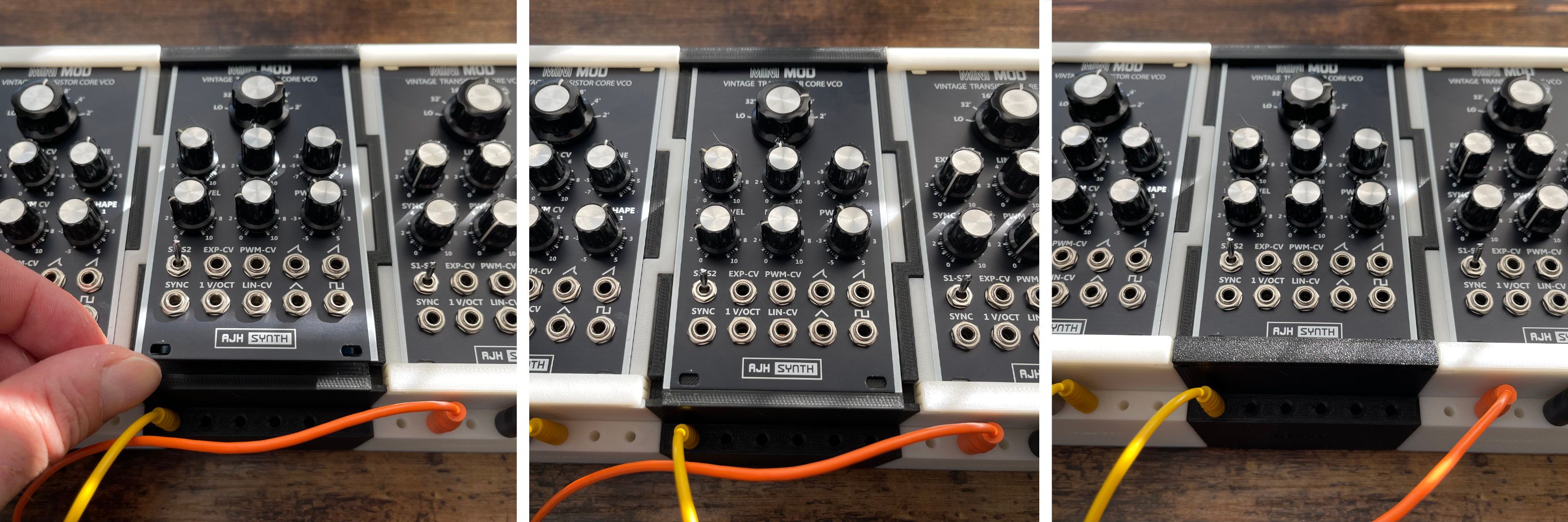

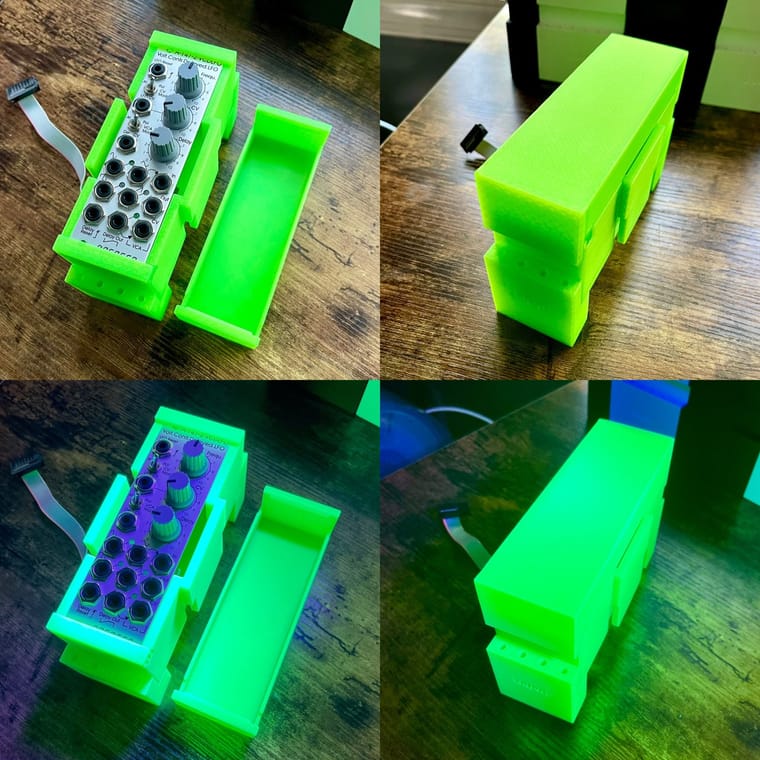

Modules are added without the need for screws, they slot into a back slot and then a cover snaps in place to keep the front tightly pressed down.

Each module can have its own case box and can sturdily slide together with other boxes in any arrangement.

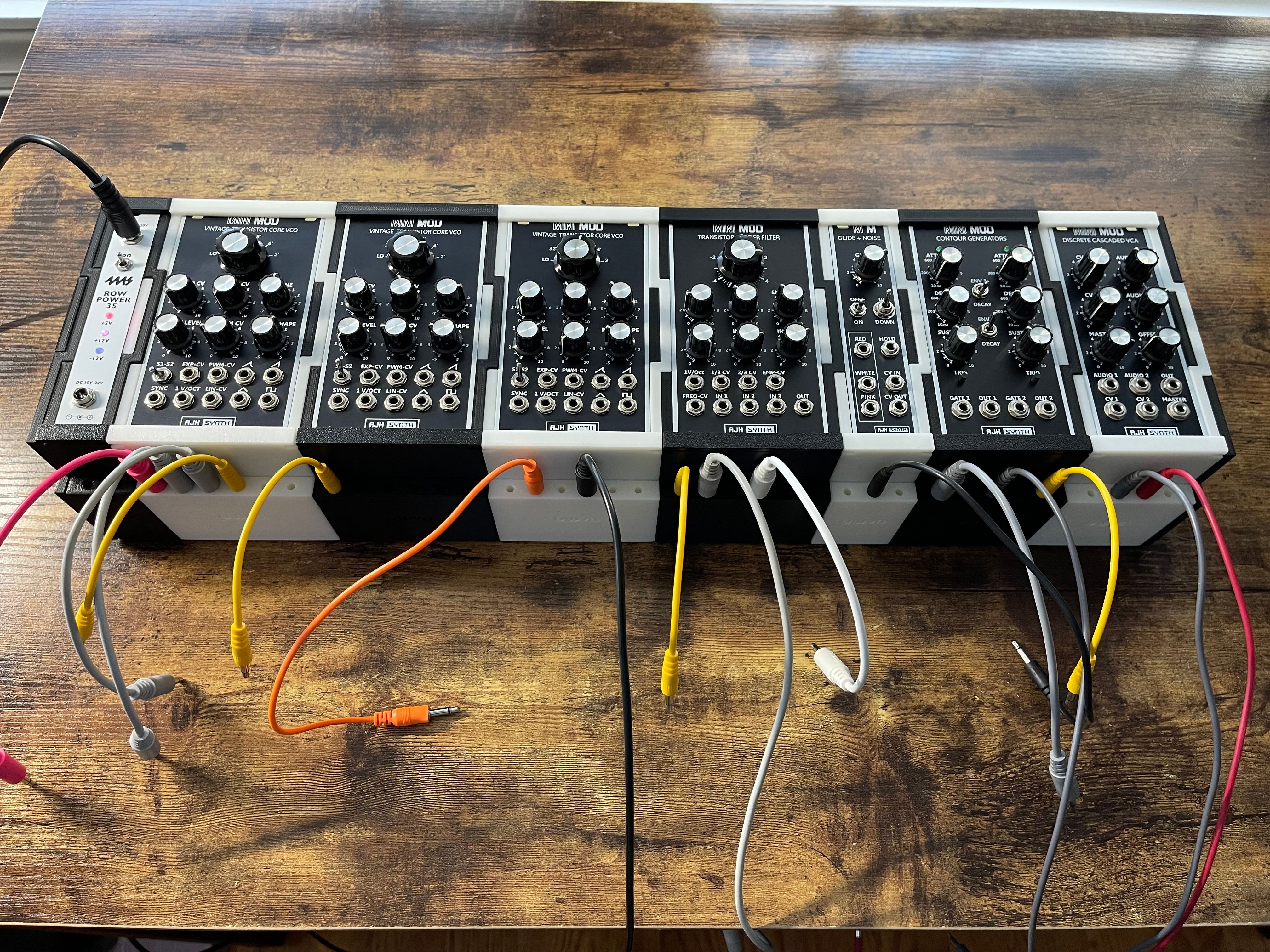

The back side of the boxes can be removed for easy access to connectors. Modules are connected to power through a flying bus cable and a 4ms Row Power module. Edges on the sides finish the complete case off nicely.

Holes on the front back sides can hold 3.5mm cables that you're not using for patching.

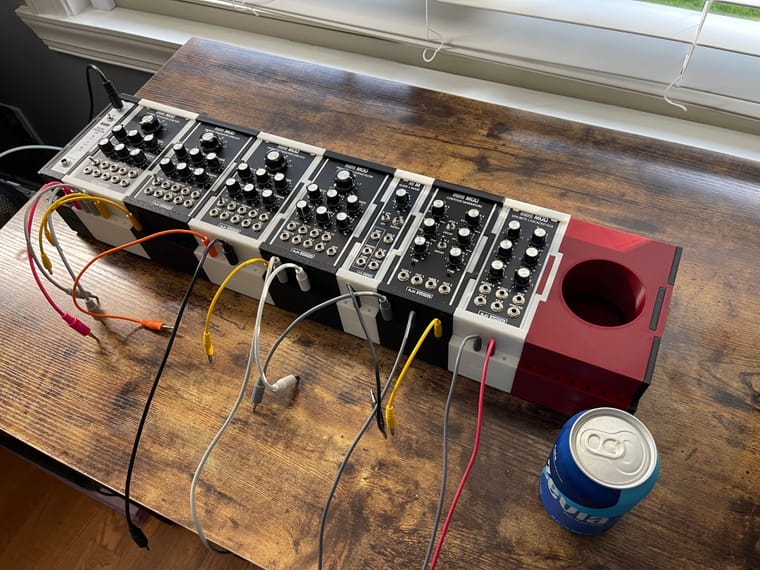

Once assembled, each case box can still be rearranged, new modules can be added.

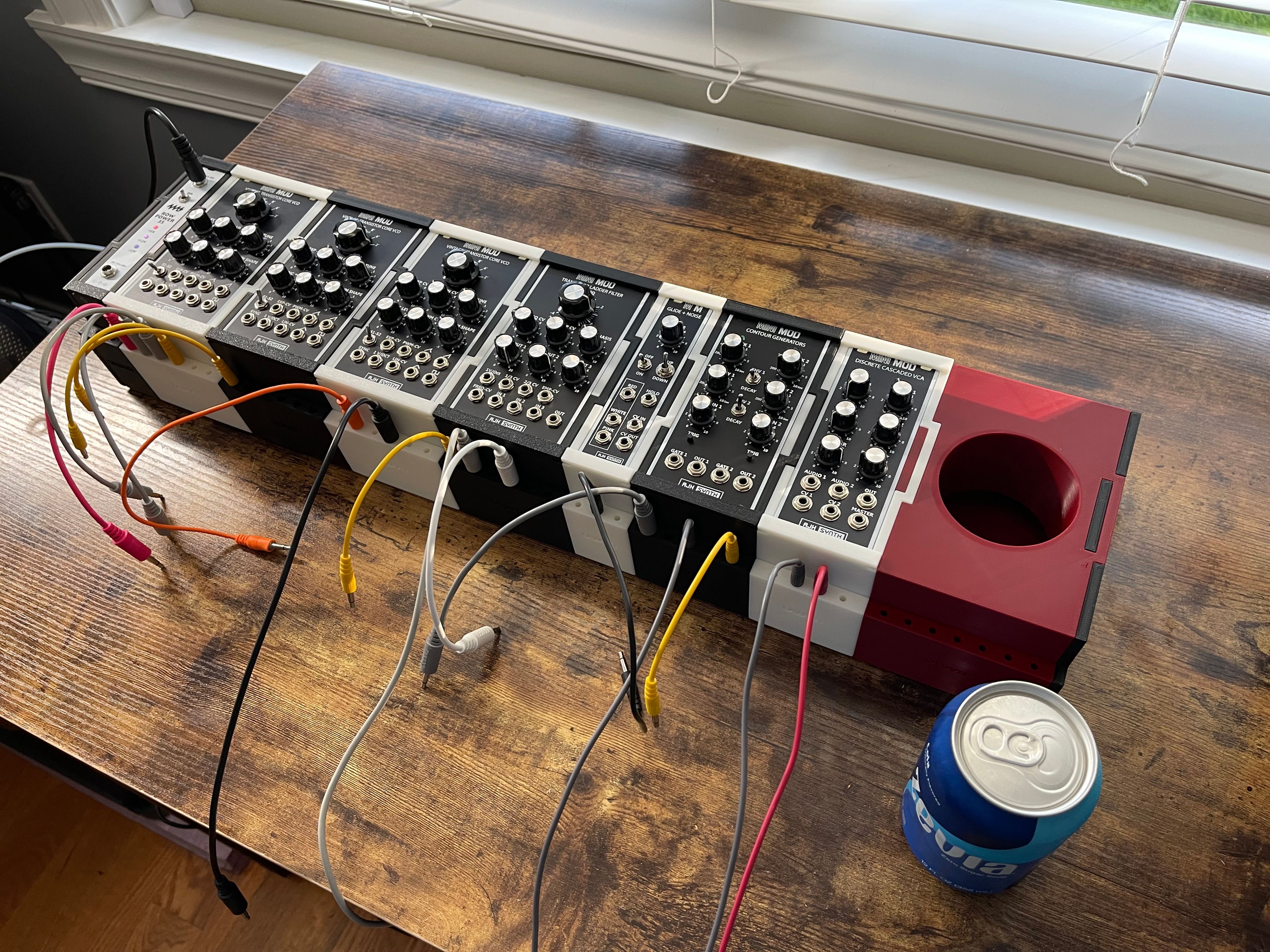

This is a prototype of a sturdy can holder that prevents any accidental split from happening.

I'm considering open sourcing it so that the community can use the connection mechanisms to build out more case boxes that could be useful.

I'm curious to hear any thoughts and comments about this system.

more details about the design stages of this effort can be found in this thread

-

Been following the progress of this on Mastodon and this is yet one more reason for me to finally go out and get a 3D printer, especially if you do decide to open-source it. I have to say that I was deeply concerned and could not figure out what on earth you were thinking when you decided to put those weird patch points on the bottom of each case, so I was definitely relieved when I read this post and realized they were "merely" patch cord storage LOL

-

Been following the progress of this on Mastodon and this is yet one more reason for me to finally go out and get a 3D printer, especially if you do decide to open-source it. I have to say that I was deeply concerned and could not figure out what on earth you were thinking when you decided to put those weird patch points on the bottom of each case, so I was definitely relieved when I read this post and realized they were "merely" patch cord storage LOL

@selgart these would be a good entry into 3D printing since they're actually pretty easy to print, so you can focus on getting to know what needs to be learned in the 3D printing realm. Yeah the cable holders are inspired by my CableCube product, though don't have the clicky feel since that wasn't possible with the rest of the design

-

G gbevin referenced this topic on

G gbevin referenced this topic on

-

Been thinking about these a bit. Would it be possible to make some sort of “negative” of the patch cable storage section? In other words, you’d have a block the size of two patch cable bits, as if the bottom of one module were to combine with the top of another, with two rows of pins pointing downwards so you could connect two single rows together to make a two-row system.

-

Been thinking about these a bit. Would it be possible to make some sort of “negative” of the patch cable storage section? In other words, you’d have a block the size of two patch cable bits, as if the bottom of one module were to combine with the top of another, with two rows of pins pointing downwards so you could connect two single rows together to make a two-row system.

-

Test printing the last sizes: 16hp, 18hp, 20hp and then I think I'm ready to release the first version of RackBlox.

Now featuring a drink koozie as well as a drink holder.

The double wall with a sealed air gap between makes for an excellent insulator and keeps your next drink cold, while you're enjoying the current one 😁

-

G gbevin moved this topic from 3D Printing & Design on

G gbevin moved this topic from 3D Printing & Design on